Hello, friend today we'll talk About Cable Tray, How Many Types Of Cable Trays, Types Of Cable Tray, Cable Tray Size And Use,

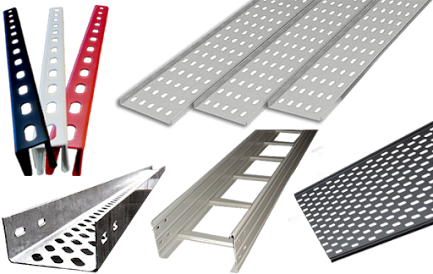

Cable trays area unit product of either steel, aluminum, or storyteller bolstered plastic (FRP) and area unit on the market in six basic varieties,

1. Ladder sort Cable tray

2. Solid Bottom Cable tray

3. Trough Cable tray

4. Channel Cable tray

5. Wire Mesh Cable tray

6. Single Rail Cable tray

(1) Ladder

Cable Tray

typically utilized in applications with intermediate to long support spans twelve to thirty feet.

Ladder cable tray is employed for regarding seventy-five p.c of the cable tray wiring system installations. it's the predominate cable tray sort thanks to its several fascinating features:

A ladder cable tray while not covers permits the utmost free flow of air across the cables. this enables the warmth created within the cable’s conductors to effectively dissipate. beneath such conditions, the conductor insulation within the cables of a properly designed cable tray wiring system won't exceed its most operative temperature. The cables won't untimely age thanks to excessive operative temperatures.

The footboard of the ladder cable trays gives suitable anchors for attachment down the cables within the non-horizontal cable storehouse runs or wherever the positions of the cables should be maintained within the horizontal cable tray runs. This capability could be a should for single conductor cable installations.

Cables could exit or enter the ladder cable trays through the highest or all-time low of the cable tray. wherever the cables enter or exit the passage, the passage to cable tray clamps could also be put upright or inverted to terminate conduits on the highest or bottom of the cable tray aspect rail.

wetness can’t accumulate in ladder cable trays

If cable trays area unit being put in wherever operating house could be a drawback, hand access through the cable tray bottom could facilitate to facilitate the installation of little diameter cables: management instrumentation, signal, etc.

the foremost common rung spacing for the ladder cable tray is nine inches. This spacing could also be accustomed to support all sizes of cables. This spacing is fascinating for the tiny diameter sort PLTC and TC cables because the support distance is such there's no visible drooping of the tiny cables between rungs. twelve or eighteen in. rung spacing provides adequate cable support but the slight amount of very little diameter cable drooping between rungs might even be aesthetically objectionable for a couple of installations. the utmost allowable distance between supports for 1&0 through 4&0 AWG single conductor cables is 9 inches,

oxygenated Trough Cable receptacle

the sole reason to pick out an oxygenated trough cable tray over a ladder sort cable tray is aesthetics. No drooping of little cables is visible. The oxygenated trough cable tray will give additional support to the cables than will the ladder cable tray however this extra support isn't vital. It doesn’t have any impact on the cable service record or life.

Characteristics:

Solid aspect rail protection and system strength with sleek radius fittings.

most strength for long span applications

commonplace widths of half-dozen, 12, 18, 24, thirty & thirty-six inches

commonplace depths of three, 4, five & half-dozen inches

commonplace lengths of ten, 12, twenty & twenty-four feet

Rung spacing of half-dozen, 9, twelve & eighteen inches.

(2) Solid Bottom Cable Tray:

typically used for the smallest heat generating electrical or telecommunication applications are available to 5 to 12 feet.

this is the Most running tray for the solid bottom with covers tray is that the aftercare of EMI, RFI, Preservation protection for the Very sensitive circuit, a solid bottom steel cable tray, with steel covers provides an honest degree of protection if there are not any breaks or holes within the completed installation.

The solid bottom cable tray system contains a disadvantage in this wetness will build up within the cable trays. this may be controlled by drilling 1/4 in. drain holes within the bottom of the cable tray at 3-foot intervals (at the center and extremely close to the sides) if the cable receptacle isn't being employed for EMI/RFI shielding.

The cable trays area unit simply supporting cables that area unit designed for such installations. Cable failures in cable tray run seldom happen. Cable failures thanks to cable support issues in cable trays area unit nonexistent.

Characteristics:

Non-ventilated continuous support for delicate cables with accessorial cable protection on the market in gilded and covering material

Solid bottom gilded with solid metal covers for non-plenum rated cable in environmental areas

commonplace widths of half-dozen, 12, 18, 24, thirty & thirty-six inches

commonplace depths of three, 4, five & half-dozen inches

commonplace lengths of ten, 12, twenty & twenty-four feet

(3) Trough Cable Tray

typically used for average heat generating applications with Intermediary support extent 5 to 12 feet

Characteristics:

Moderate ventilation with accessorial cable support frequency with all-time low configuration providing cable support every four inches.

on the market in metal and metalloid materials

commonplace widths of half-dozen, 12, 18, 24, thirty & thirty-six inches

commonplace depths of three, 4, five & half-dozen inches

commonplace lengths of ten, 12, twenty & twenty-four feet

mounted rung spacing of four inches on center.

(4) Channel Cable Tray

Used for installations with restricted numbers of tray cable once the passage is undesirable. Support frequency with short to medium support spans five to ten feet.

Characteristics:

Economical support for cable drops and branch cable runs from the backbone cable receptacle system

commonplace widths of three, 4, & half-dozen inches in metal systems and up to eight inches in metalloid systems

commonplace depths of one one/4 to one 3/4 inches in metal systems and 1, 1 1/8, one 5/8 in metalloid systems

commonplace length of ten, 12, twenty & twenty-four feet.

(5) Wire Mesh Cable Tray

typically used for telecommunication and fiber optic applications, put in on short support spans—4 to eight feet.

Characteristics

employment website, field adjustable web primarily for low voltage, telecommunication, and fiber optic cables.

These systems area unit usually steel wire mesh, atomic number 30 plated

commonplace widths of two, 4, 6, 8, 12, 16, 18, twenty & twenty-four inches

commonplace depths of one, a pair of & four inches

commonplace length of regarding ten feet.

(6) Single Rail Cable Tray

typically used for low voltage and transmission line installations wherever most cable freedom, aspect fill, and speed to put in area unit factors.

Characteristics

These Al systems area unit the quickest systems to put in and supply the utmost freedom for cable to enter and exit the system

Single decorated or wall-mounted systems in single or multiple tiers

commonplace widths area unit half-dozen, 9, 12, eighteen & twenty-four inches

commonplace depths area unit three, four & half-dozen inches

commonplace lengths area unit ten & twelve feet.

Cable tray use for electrical cable distribution in the building’s structural plants and pipe racks, cable laying cable routing at cable tray also use for protection. Cable tray use for all control and power cables cable tray also use as a mechanical protection of cable protect from falling of any object directly at live cable, cable trays are manufactured of different types.

ReplyDeleteCable ladder

Perforated cable tray

Cable duct

Cable Mesh

Cable tray made of different material like mild steel, stainless steel, aluminum and fiber glass/PVC.

Cable tray fabricated from mild steel for perforation use cnc laser cutting and auto rolling forming machinery and other manual bending punching and dip in the hot zinc or powder coating , painting for protection from rusting, as per atmosphere condition some time we use stainless steel or aluminum or fiber glass. Selection of material depends on area condition, we can install the cable tray at structure with the walls of hang from roof with the help of rods, some time we use the cover at tray to protect the cables from sun light, cable tray is the part of electrical installation, perforation in the cable tray help out to exhaust the heat of power cable due to ventilation we can reduce the cable temperature.

Cable tray in Pakistan

Types of Cable Typically Used in Cable Tray

ReplyDeleteThe purpose of a cable tray system is to support, route, and protect cable as part of the cable management system. Through NEMA and the Cable Tray Institute numerous articles, standards, and other general guidance can be found regarding the proper use and installation of cable tray systems.

Cable Tray

Cable tray used for electrical cable distribution in the building’s structural plants and pipe racks, cable laying cable routing at cable tray also use for protection. Cable tray used for all control and power cables cable tray also use as mechanical protection of cable protect from falling off any object directly at the live cable, cable trays are manufactured of different types.

ReplyDeleteCable ladder

Perforated cable tray

Cable duct

Cable Mesh

Cable Tray Accessories

Classification, Design and accessories of Cable Tray:

ReplyDeleteCable tray can be fabricated and design according to industrial usage and plant specifications; it could be in following types;

Ladder Cable tray:

A stair type ladder tray consists of Rungs which is joint by two sheet walls. It has relevantly less weight.

Perforated Cable tray:

Design, bend and fabricated a one piece of material and perforated by punches. It has high weight as compared to Ladder cable Tray.

Cable Tray

Post a Comment

Please Don't Write & Enter Here Any Spam link In The Comment Box Thank You!